ASME Process Piping

ASME Process Piping

The American Society of Mechanical Engineers (ASME) established ASME B31.3 and ASME B31.8 also known as the Process Piping Code, to provide guidelines for pressure piping in various industries to ensure their safety and reliability. The code outlines standardized practices and requirements widely used by engineers, designers, and industry professionals involved in piping systems’ design, construction, and maintenance.

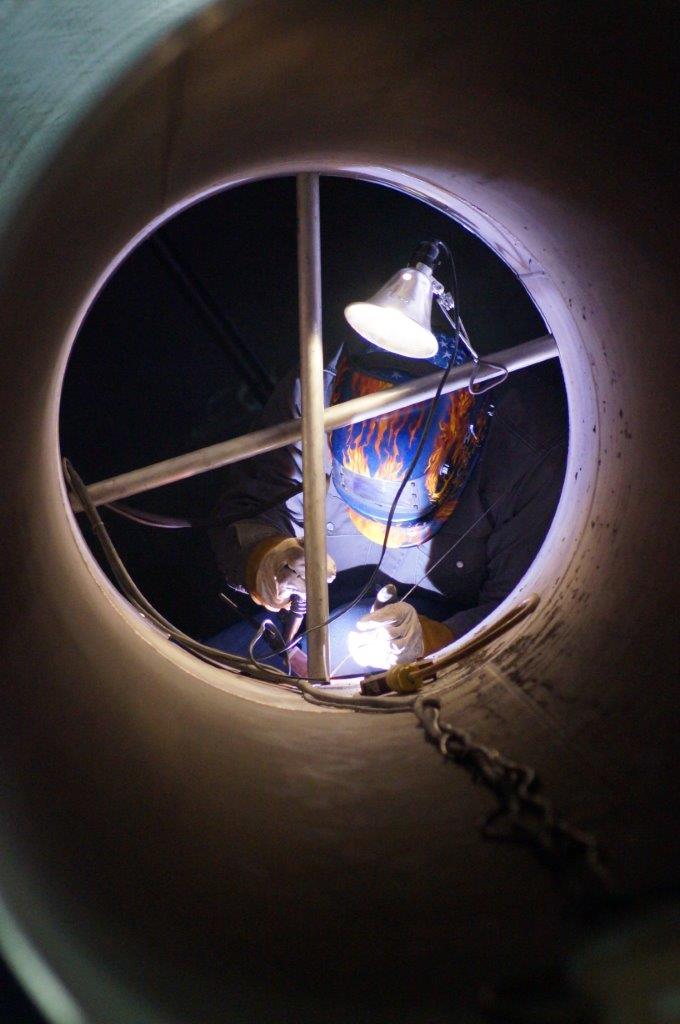

In line with these standards, Precision Welding and Fabrication stands as a comprehensive service provider specializing in the fabrication of process piping. Our expertise spans various alloys, including stainless and duplex, further ensuring the compliance and high-caliber execution demanded by ASME B31.3 and ASME B31.8. Learn more about ASME process piping, the applications covered by the code, and more.

Overview of ASME Process Piping

ASME B31.3 and ASME B31.8 outline guidelines for the safe design, manufacture, assembly, and operation of process piping systems by process plants and pipeline equipment. ASME B31.3 and B31.8 lay out the minimum requirements for how these piping systems should be designed, constructed, fabricated, tested, and inspected.

It also specifies the materials to be used in the systems. Depending on their intended application, materials for process piping are rated based on corrosion resistance, strength, and other mechanical properties. The materials used should be able to withstand the pressure, temperature, and other conditions of the operating environment. Common materials for process piping systems include:

- Aluminum

- Stainless steel

- Carbon steel, 516-70, A36, X70, and X65

- Copper Nickel

- Duplex Stainless

- 4130 and Dissimilar Weld Metals

- Inconel, Monel, and Hastelloy

In this context, Precision Welding and Fabrication stands as a vital partner. Our skilled fabrication team, backed by an effective and flexible management team, possesses an intimate familiarity with the intricacies of codes, standards, procedures, and industrial regulations. This expertise seamlessly aligns with ASME B31.3 and B31.8 standards, enabling us to navigate the landscape of designing, constructing, fabricating, testing, and inspecting these intricate piping systems with precision. As a process-oriented company, we’re dedicated to meticulous execution, and our commitment extends further with the added capability of expedited delivery, ensuring not only compliance but also efficiency in every project we undertake.

Industries and Applications of ASME Process Piping

Process piping facilitates the safe and efficient flow of fluids such as slurries, liquids, and gases. The subsections of ASME B31.3 and B31.8 outline the particular requirements of each type of process media and application. ASME process piping is used to deliver substances in processing facilities in these industries and applications:

- Flare, Derricks, and Stacks

- Pulp & paper processing facilities

- Space

- Defense

- Cryogenic plants

- Petroleum refineries

- Petroleum & natural gas production facilities

- Food & beverage processing facilities

ASME Process Piping Capabilities

Full-service welding and fabrication of ASME piping, fabricated large diameter pipe, pipe bending and rolling, hydro-testing, hydraulic torque bolting, and non-destructive testing.

ASME Process Piping From Precision Welding & Fabrication

The quality of a facility’s products depends on the quality of its process piping. At Precision Welding and Fabrication, we have assembled a team of seasoned experts with extensive experience in welding and fabricating process piping systems for a multitude of industries. Our track record speaks volumes, boasting a remarkable repair ratio of less than 1/10 of 1% since 1983. This level of precision and reliability underscores our commitment to excellence in every aspect of our work. We adhere to ASME B31.3 and B31.8 standards, as well as API 1104 standards to ensure the systems provide optimal control over temperature, pressure, and flow rate based on our clients needs. Contact us today for more information, or request a quote for specific pricing details.

ASME Process Piping

ASME Process Piping